Propeller & Boiler

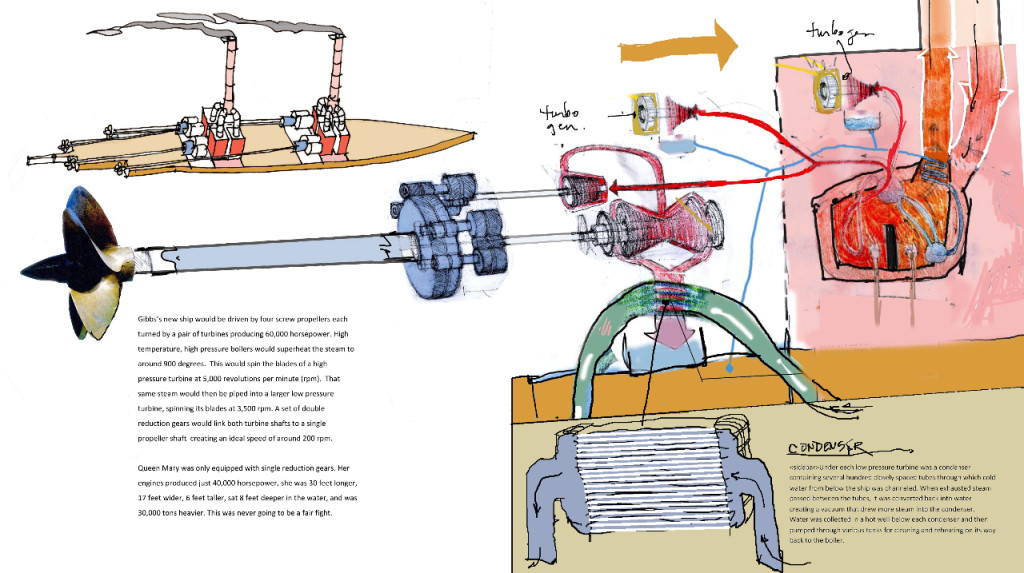

In this two-page spread, Macaulay examines the interaction between the propeller and the boiler. Gibbs' new ship would be driven by four screw propellers each turned by a pair of turbines producing 60,000 horsepower. High temperature, high pressure boilers would superheat the steam to around 900 degrees. This would spin the blades of a high pressure turbine at 5,000 revolutions per minute (rpm). That same steam would then be piped into a larger low pressure turbine, spinning its blades at 3,500 rpm. A set of double reduction gears would link both turbine shafts to a single propeller shaft creating a ideal speed of around 200 rpm. Under each low pressure turbine was a condenser containing several hundred closely-spaced tubes through which cold water from below the ship was channeled. When exhausted steam passed between the tubes, it was converted back into water, creating a vacuum that drew more steam into the condenser. Water was collected in a hot well below each condenser and then pumped through various tubes for cleaning and reheating on its way back to the boiler. He also compares the Big U's engine to the Queen Mary's.Queen Mary was equipped with single reduction gears. Her engines produced just 40,000 horsepower, she was 30 feet longer, 17 feet wider, 6 feet taller, sat 8 feet deeper in the water, and was 30,000 tons heavier. This was never going to be a fair fight.

Gibbs' new ship would be driven by four screw propellers each turned by a pair of turbines producing 60,000 horsepower. High temperature, high pressure boilers would superheat the steam to around 900 degrees. This would spin the blades of a high pressure turbine at 5,000 revolutions per minute (rpm). That same steam would then be piped into a larger low pressure turbine, spinning its blades at 3,500 rpm. A set of double reduction gears would link both turbine shafts to a single propeller shaft creating a ideal speed of around 200 rpm. Under each low pressure turbine was a condenser containing several hundred closely-spaced tubes through which cold water from below the ship was channeled. When exhausted steam passed between the tubes, it was converted back into water, creating a vacuum that drew more steam into the condenser. Water was collected in a hot well below each condenser and then pumped through various tubes for cleaning and reheating on its way back to the boiler. He also compares the Big U's engine to the Queen Mary's.Queen Mary was equipped with single reduction gears. Her engines produced just 40,000 horsepower, she was 30 feet longer, 17 feet wider, 6 feet taller, sat 8 feet deeper in the water, and was 30,000 tons heavier. This was never going to be a fair fight.